Spectrum Single-Jets

Applications

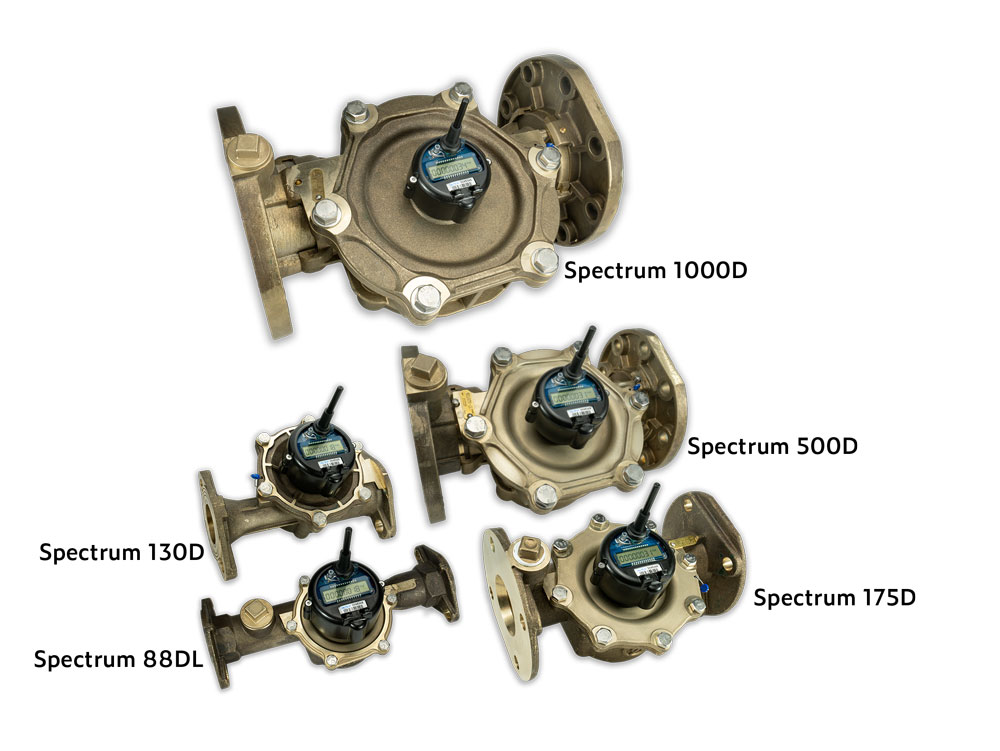

The Spectrum Single-Jet Meter is the widest ranged, single-measuring element meter available to U.S. utilities. The operation of the single jet element allows the meter to be applied in the vast majority of potable cold water, small commercial applications. These meters are designed with a very high range, including low flow performance equaling or exceeded all other metering technologies. Coupled with the advanced innov8 registers, the Spectrum single-jets are the meter of choice for your revenue assurance and water loss programs.

All Spectrum Model-D meters are top-loading, chamber designs which allow for field maintenance and repairs.

Operations

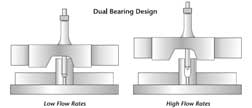

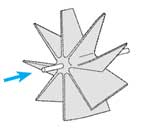

Incoming water rotates a suspended impeller that is magnetically linked to the register. A low friction tungsten carbide bearing supports the impeller at low flow rates while a tungsten carbide thrust bearing provides the support at high flow rates. This unique “dual bearing” design provides unparalleled accuracy and durability at both high and low flows.

All Spectrum Model D meters utilize innov8 registers. These sealed electronic registers provide a high resolution interface to the meter and have multiple cellular, AMR, AMI and SCADA outputs. All registers are attached with a robust tamper-resistant housing.

Design Features

- High accuracy below AWWA standards

- Wide range—1000:1 turndown

- Superior low flow registration

- Compact and light

- Convenient options for various lengths and connections

- Low pressure drop

- No regular maintenance

- Excellent performance in adverse water conditions

- Unaffected by sand or small debris in line

- No straight pipe requirements – upstream or downstream

- No strainer requirement

- 5-year flange-to-flange warranty

- 20-year warranty on meter body

- Compatible with all innov8 registers and associated AMR/AMI capabilities.

All Spectrum Model-D meters are designed and manufactured to meet or exceed AWWA C712 standard design and performance specifications. All Models are maintained with NSF-61G lead-free certifications.

Standards

AWWA C712 – Single-Jet Meters

NSF-61G – Drinking Water System Components Health Effects

Mechanical Specifications

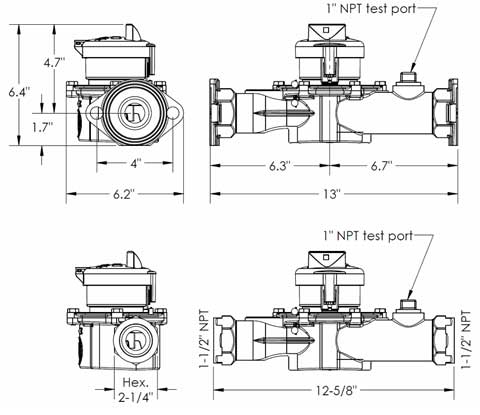

| Spectrum 88DL | 1.5-inch (40mm) | |

| Flanges | Oval 2-bolt | |

| Lay Length | 13” (330 mm) | |

| Dimensions | See drawing | |

| Weight | 32lb (14.5 kg) | |

| Test Plug | 1” Integral | |

| Test Port | Integral 1” NPT threads | |

| Spectrum 88DLT | 1.5-inch (40mm) | |

| Connection | Female 1.5” / 11.5 NPT internal threads | |

| Lay Length | 12.625” (319 mm) | |

| Dimensions | See drawing | |

| Weight | 32lb (14.5 kg) | |

| Spectrum 130D | 2-inch (80mm) | |

| Flanges | Oval 2-bolt | |

| Lay Length | 9.75” (300 mm) | |

| Dimensions | See drawing | |

| Weight | 32lb (14.5 kg) | |

| Test Plug | Available on spool | |

| Brass Spacer Spools* | Lead-free flanged spools for 15.25” and 17” LL | |

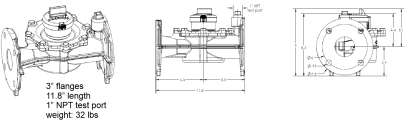

| Spectrum 175D | 3-inch (80mm) | |

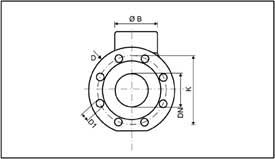

| Flanges | Round 4-bolt | |

| Lay Length | 11.8” (300 mm) | |

| Dimensions | See drawing | |

| Weight | 32lb (14.5 kg) | |

| Z-Plate Strainer* | Available (6” LL) | |

| SS Spacer Spools* | Hard-flanged or adjustable | |

| Test Port | Integral 1” NPT threads | |

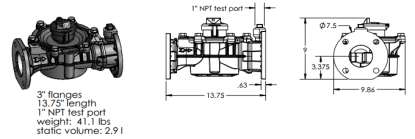

| Spectrum 500D | 3-inch (80mm) | 4-inch (100mm) |

| Flanges | Round 4-bolt | Round 8-bolt |

| Lay Length | 13.75” (349 mm) | 13.75” (349 mm) |

| Dimensions | See drawing | See drawing |

| Weight | 41lb (18.6 kg) | 48lb (21.7 kg) |

| Z-Plate Strainer* | Available (6” LL) | Available (7.5” LL) |

| SS Spacer Spools* | Hard-flanged or adjustable | Hard-flanged or adjustable |

| Test Port | Integral 1” NPT threads | Integral 1” NPT threads |

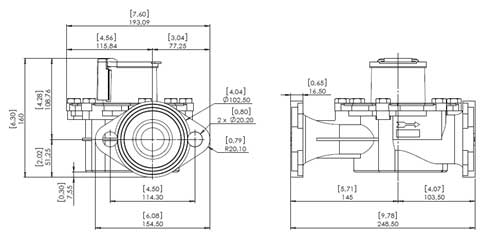

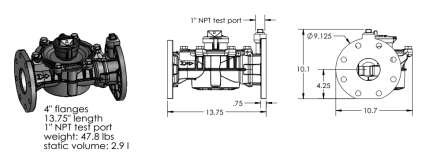

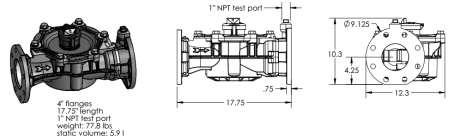

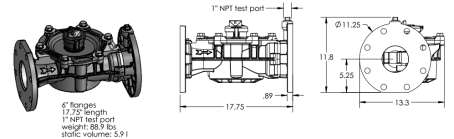

| Spectrum 1000D | 4-inch (100mm) | 6-inch (150mm) |

| Flanges | Round 8-bolt | Round 8-bolt |

| Lay Length | 17.75” (349 mm) | 17.75” (349 mm) |

| Dimensions | See drawing | See drawing |

| Weight | 78lb (35.4 kg) | 89lb (40.4 kg) |

| Z-Plate Strainer* | Available (7.5” LL) | Available (8.9” LL) |

| SS Spacer Spools* | Hard-flanged or adjustable | Hard-flanged or adjustable |

| Test Port | Integral 1” NPT threads | Integral 1” NPT threads |

| * Contact Metron for information on brass spools and couplers. | ||

Materials

| Body & Top-plate: | ASTM C875 – Lead Free Bronze |

| Impeller: | Polypropylene |

| Impeller Bearings: | Nylon with Carbon Fiber |

| Impeller Shaft: | AISI 303, Tungsten Carbide tip |

| Register Housing: | Thermoplastic |

Tamper Features

| Meter Body | Wire +Lead seal between meter body and top-plate |

| Register | Tamper-resistant screw |

Markings

| Engraved on Meter Body: | Model |

| Serial Number | |

| Date of Manufacture | |

| NSF-6 | |

| Direction of Flow |

Dimension

| Spectrum 88DL 1.5-Inch Models | Spectrum 130D 2-Inch Model |

|  |

| Spectrum 175D 3-Inch Model | Spectrum 500D 3-Inch Model |

|  |

| Spectrum 500D 4-Inch Model | Spectrum 1000D 4-Inch Model |

|  |

| Spectrum 1000D 6-Inch Model | |

| |

Flow and Pressure Specifications

Spectrum 88DL / 88DLT– 1.5” Models

| Operating Range (98.5 to 101.5%) | 0.5 to 105 gpm | (0.11 to 24 m3/hr) |

| Low Flow (95% min) | 0.25 gpm | (0.057 m3/hr) |

| Max Continuous Flow1 | 88 gpm | (20 m3/hr) |

| Max Intermittent Flow2 | 105 gpm | (24 m3/hr) |

| Pressure Loss at Max Continuous | 7.25 psi | (0.5 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Spectrum 130D – 2” Model

| Operating Range (98.5 to 101.5%) | 0.75 to 165 gpm | (0.17 to 37.5 m3/hr) |

| Low Flow (95% min) | 0.25 gpm | (0.057 m3/hr) |

| Max Continuous Flow1 | 130 gpm | (29.5 m3/hr) |

| Max Intermittent Flow2 | 165 gpm | (37.5 m3/hr) |

| Pressure Loss at Max Continuous | 7.25 psi | (0.5 bar) |

| Max Operating Pressure | 230 psi | (15.9 kPa) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Spectrum 175D – 3” Model

| Operating Range (98.5 to 101.5%) | 0.75 to 350 gpm | (0.17 to 79.5 m3/hr) |

| Low Flow (95% min) | 0.5 gpm | (0.11 m3/hr) |

| Max Continuous Flow1 | 175 gpm | (39.74 m3/hr) |

| Max Intermittent Flow2 | 245 gpm | (55.6 m3/hr) |

| Peak Flow Test | 350 gpm | (79.49 m3/hr) |

| Pressure Loss at Max Continuous | 7.25 psi | (0.5 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Spectrum 500D – 3″ / 4” Model

| Operating Range (98.5 to 101.5%) | 1.5 to 500 gpm | (0.34 to 113.5 m3/hr) |

| Low Flow (95% min) | 0.75 gpm | (0.17 m3/hr) |

| Max Continuous Flow1 | 350 gpm | (79.5 m3/hr) |

| Max Intermittent Flow2 | 500 gpm | (113.5 m3/hr) |

| Peak Flow Test | 600 gpm | (136 m3/hr) |

| Pressure Loss at Max Continuous | 7.25 psi | (0.5 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Spectrum 1000D – 4″ / 6” Model

| Operating Range (98.5 to 101.5%) | 2 to 1000 gpm | (0.45 to 227.12 m3/hr) |

| Low Flow (95% min) | 1.0 gpm | (0.23 m3/hr) |

| Max Continuous Flow1 | 600 gpm | (136 m3/hr) |

| Max Intermittent Flow2 | 1000 gpm | (227.125 m3/hr) |

| Peak Flow Test | 1100 gpm | (249.83 m3/hr) |

| Pressure Loss at Max Continuous | 7.25 psi | (0.5 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Notes

- 1 Max Continuous defined by AWWA as flow rate which can be maintained 24 hrs/day x 7 days/week

- 2 Max Intermittent defined as flow rate which can be maintained 1 hr/day average

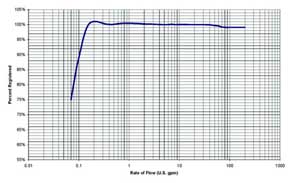

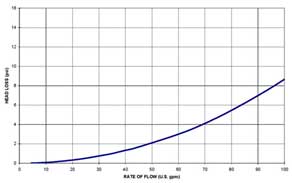

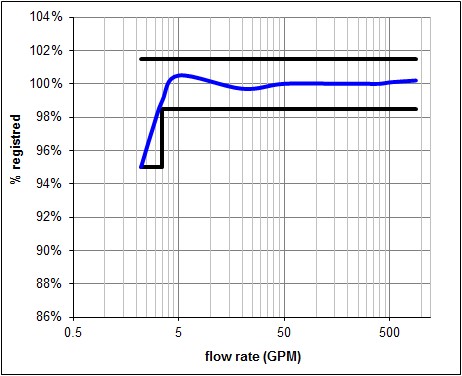

Flow Accuracy and Pressure Drop

| Flow Accuracy | Pressure Drop |

Spectrum 88DL / 88 DLT |  |

Spectrum 130D |  |

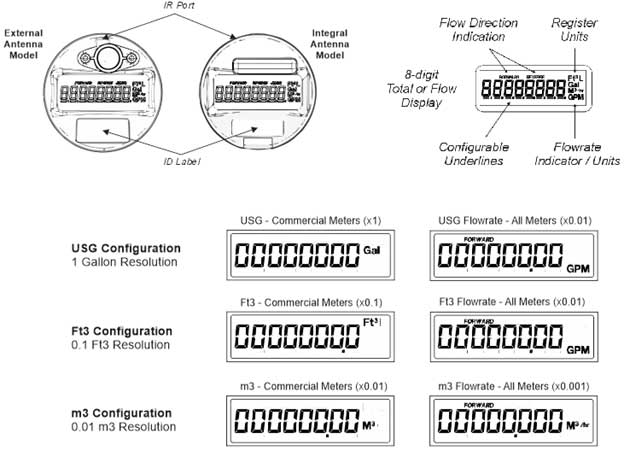

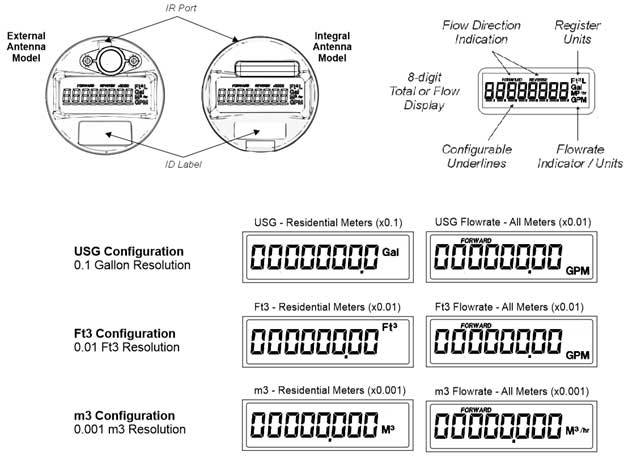

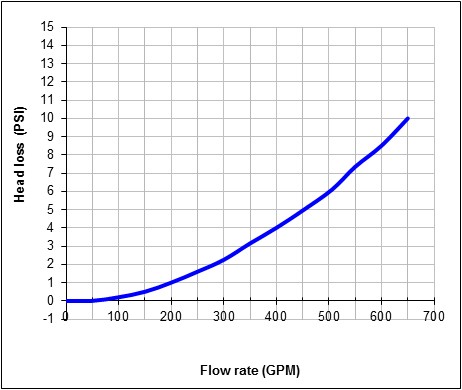

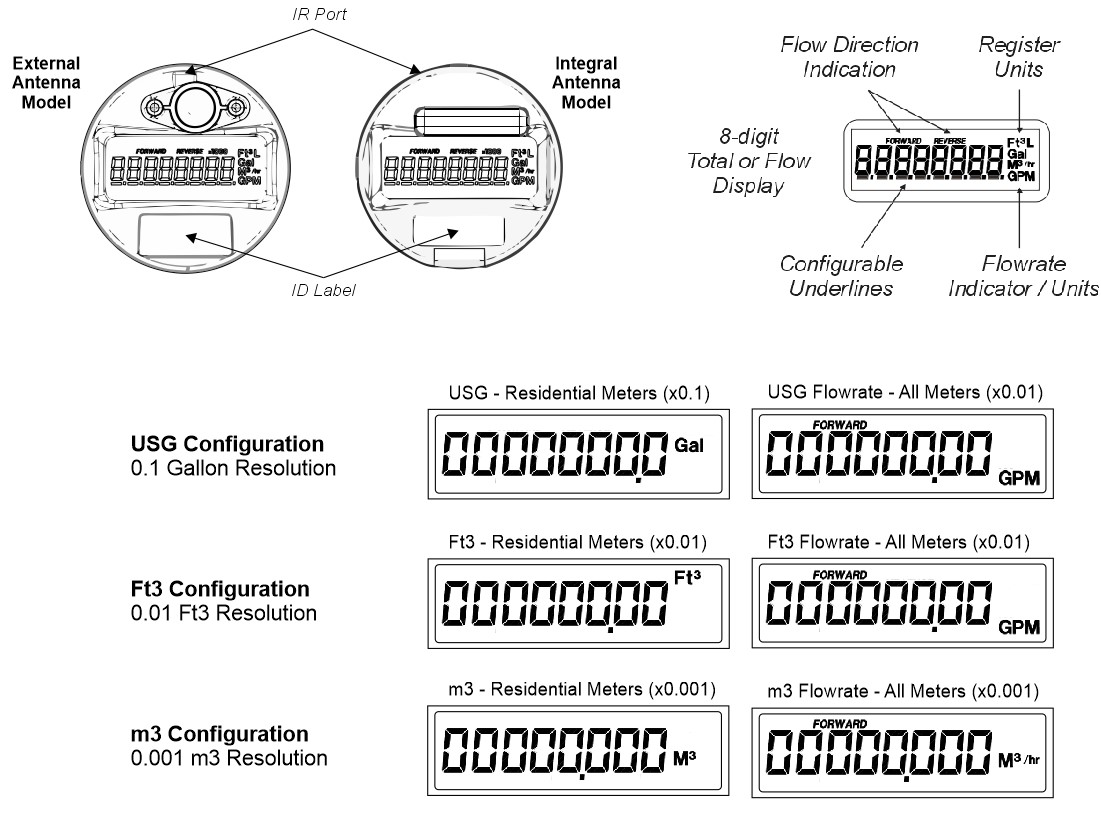

Registers

The innov8 electronic register is the water industry’s new standard for register performance. The innov8 offers maximum resolution, a multitude of standard features, on-board datalogging and a variety of cellular, AMI, AMR and SCADA output options. The innov8 is designed for all environments and incorporates the largest battery available for utility applications. The innov8 can be deployed on any Metron Spectrum or Enduro Model D water meter.

Warranty

Please contact your Metron representative for formal warranty certificates.

Legal

Due to updated regulations and product improvements, Metron-Farnier reserves the right to change the product specifications without notice.

Challenger Turbines

Applications

The Challenger turbine meters are an ideal choice for the most challenging metering applications. These turbine meters are the defacto choice for consistent medium to high flow and immediate flow demand applications such as large-scale irrigation, high-rise building services and manufacturing. The Challenger is a compact, top-loading meter which can be adapted for almost any location, including vertical installations. While the Challenger meters do offer good low-flow capabilities, their primary application is for long-term performance and durability at high flowrates.

All Spectrum Model-D meters are top-loading, chamber designs which allow for field maintenance and repairs.

Operations

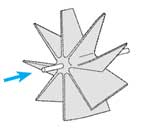

The Challenger meters utilize an innovative bearing design based on the proven Woltman turbine concept. A turbine is mounted on a shaft oriented parallel to the flow stream. The water forces the blades of the turbine to rotate the shaft in proportion to the velocity of the flow.

All Challenger turbine meters utilize innov8 registers. These sealed electronic registers provide a high resolution interface to the meter and have multiple cellular, AMR, AMI and SCADA outputs. All registers are attached with a robust tamper-resistant housing.

Design Features

- Light & compact with short length

- Wide accuracy range

- Horizontal or vertical installation

- Calibrate-able measuring chamber

- Field replaceable measuring chamber

- Outstanding long-term accuracy through hydraulic bearing relief

- Register head can be rotated 365o for easier reading

- Compatible with all Innov8 electronic registers

- AMI/AMR and SCADA outputs available

Materials

The Altair meters are designed and manufactured to meet

or exceed AWWA C701 Class II standards design and performance specifications. All Models are maintained with NSF-61G lead-free certifications.

Standards

AWWA C701 Class II

Mechanical Specifications

| Challenger 2” | 2-inch (50mm) | |

| Flanges | Round 4-bolt | Bolt Hole Diameter = 0.71” (18 mm) |

| Flange Diameter | 6.5” (165 mm) | Pattern = 4.9” (125 mm) |

| Lay Length | 7.87” (200 mm) | |

| Total Height | 7.8“ (198 mm) | Above Centerline = 4.85” (123 mm) |

| Weight | 22.5lb (10.2 kg) | |

| Challenger 3” | 3-inch (80mm) | |

| Flanges | Round 4-bolt | Bolt Hole Diameter = 0.71” (18 mm) |

| Flange Diameter | 7.87” (200 mm) | Pattern = 6.3” (160 mm) |

| Lay Length | 8.9” (225 mm) | |

| Total Height | 9.6“ (243 mm) | Above Centerline = 6.1” (154 mm) |

| Weight | 28.7lb (13 kg) | |

| Challenger 4” | 4-inch (100mm) | |

| Flanges | Round 8-bolt | Bolt Hole Diameter = 0.71” (18 mm) |

| Flange Diameter | 8.66” (220 mm) | Pattern = 7.1” (180 mm) |

| Lay Length | 9.8” (250 mm) | |

| Total Height | 10.2“ (259 mm) | Above Centerline = 6.1” (154 mm) |

| Weight | 35.3lb (16 kg) | |

| Challenger 6” LF | 6-inch (125mm) | |

| Flanges | Round 8-bolt | Bolt Hole Diameter = 0.87” (22 mm) |

| Flange Diameter | 9.8” (250 mm) | Pattern = 9.5” (240 mm) |

| Lay Length | 9.8” (250 mm) | |

| Total Height | 10.6“ (269 mm) | Above Centerline = 6.1” (154 mm) |

| Weight | 47.4lb (21.5 kg) | |

| Challenger 6” HF | 6-inch (150mm) | |

| Flanges | Round 8-bolt | Bolt Hole Diameter = 0.87” (22 mm) |

| Flange Diameter | 11.2” (285 mm) | Pattern = 9.5” (240 mm) |

| Lay Length | 11.8” (300 mm) | |

| Total Height | 15“ (380 mm) | Above Centerline = 9.65” (245 mm) |

| Weight | 86lb (39 kg) |

|  |

Materials

| Body & Top-plate: | Epoxy-coated Cast Iron |

| Register Housing: | Thermoplastic |

Markings

| Engraved on Meter Body: | NSF-61 |

| Direction of Flow Arrow |

Flow and Pressure Specifications

| Operating Range (98.5 to 101.5%) | 2.0 to 400 gpm | (0.45 to 91 m3/hr) |

| Low Flow (95% min) | 1.5 gpm | (0.35 m3/hr) |

| Max Continuous Flow1 | 175 gpm | (40 m3/hr) |

| Max Intermittent Flow2 | 400 gpm | (91 m3/hr) |

| Pressure Loss at Max Continuous | 3.6 psi | (0.25 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Challenger 3”

| Operating Range (98.5 to 101.5%) | 3.0 to 880 gpm | (0.68 to 200 m3/hr) |

| Low Flow (95% min) | 2.0 gpm | (0.5 m3/hr) |

| Max Continuous Flow1 | 500 gpm | (110 m3/hr) |

| Max Intermittent Flow2 | 880 gpm | (200 m3/hr) |

| Pressure Loss at Max Continuous | 3.6 psi | (0.25 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Challenger 4”

| Operating Range (98.5 to 101.5%) | 4.0 to 1320 gpm | (0.9 to 300 m3/hr) |

| Low Flow (95% min) | 2.0 gpm | (0.45 m3/hr) |

| Max Continuous Flow1 | 700 gpm | (160 m3/hr) |

| Max Intermittent Flow2 | 1320 gpm | (300 m3/hr) |

| Pressure Loss at Max Continuous | 5.8 psi | (0.4 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Challenger 6” LF

| Operating Range (98.5 to 101.5%) | 5.0 to 1540 gpm | (1.1 to 350 m3/hr) |

| Low Flow (95% min) | 2.5 gpm | (0.57 m3/hr) |

| Max Continuous Flow1 | 700 gpm | (160 m3/hr) |

| Max Intermittent Flow2 | 1540 gpm | (350 m3/hr) |

| Pressure Loss at Max Continuous | 5.8 psi | (0.4 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Challenger 6” HF

| Operating Range (98.5 to 101.5%) | 8.0 to 2100 gpm | (1.8 to 475 m3/hr) |

| Low Flow (95% min) | 8.0 gpm | (1.8 m3/hr) |

| Max Continuous Flow1 | 1500 gpm | (340 m3/hr) |

| Max Intermittent Flow2 | 2100 gpm | (475 m3/hr) |

| Pressure Loss at Max Continuous | 5.8 psi | (0.4 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Notes

- 1 Max Continuous defined by AWWA as flow rate which can be maintained 24 hrs/day x 7 days/week

- 2 Max Intermittent defined as flow rate which can be maintained 1 hr/day average

Registers

The innov8 electronic register is the water industry’s new standard for register performance. The innov8 offers maximum resolution, a multitude of standard features, on-board datalogging and a variety of AMI, AMR and SCADA output options. The innov8 is designed for all environments and incorporates the largest battery available for utility applications. The innov8 can be deployed on any Metron water meter.

Warranty

Please contact your Metron representative for formal warranty certificates.

Legal

Due to updated regulations and product improvements, Metron-Farnier reserves the right to change the product specifications without notice.

Voyager Smart Hydrant Meter

Applications

The Voyager 80 is a hydrant meter with a flow range suitable for measuring fire hydrants and other fire service systems. The lightweight, aluminum body meter can be fitted for any utility or construction requirements. The Voyager has a robust turbine measuring element capable of withstanding the high flow and start/stop punishment of these applications. A full cage can be provided to protect the register and optional GPS unit from damage at construction sites and during transportation.

Fitting the Voyager with an innov8-VN register conveniently provides remote cellular-based readings via Metron’s Waterscope System. This allows the utility to track reads and consumption during the meter’s field time. An optional GPS unit also allows the utility to track the location of the meter on Google™ Maps.

Operations

The Voyager meters utilize an innovative bearing design based on the proven Woltman turbine concept. A turbine is mounted on a shaft oriented parallel to the flow stream. The water forces the blades of the turbine to rotate the shaft in proportion to the velocity of the flow.

Design Features

- Calibrate-able measuring chamber

- Field replaceable measuring chamber

- Protective register cage

- Lightweight epoxy coated aluminum body

- For horizontal or vertical installation

- Outstanding long-term accuracy through hydraulic bearing relief

- Register head can be rotated 365o for easier reading

- Compatible with Innov8 VN electronic registers

- Optional GPS tracking device

Materials

The Voyager meters are designed and manufactured to meet or exceed AWWA C701Class II standards design and performance specifications.

Standards

AWWA C701 Class II

Mechanical Specifications

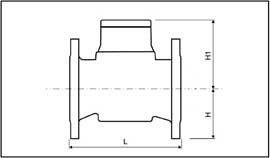

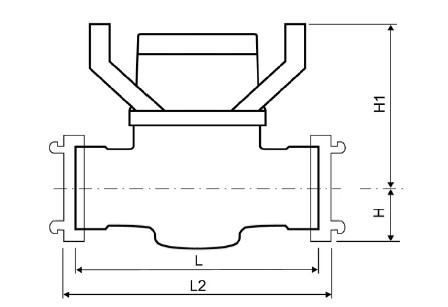

Dimensions

| Size | 3” |

| Nominal Thread Diameter | 2.5” |

| Lay Length (no couplings) L | 11.8” |

| Overall Height | 9.875” |

| Bottom Centerline Height H | 3.375” |

| Top Centerline Height H1 | 5.5” |

Materials

| Body & Top-plate: | Nylon Composite |

| Register Housing: | Thermoplastic |

Markings

| Engraved on Meter Body: | Model |

| Direction of Flow Arrow |

Flow and Pressure Specifications

| Normal Operating Range (98.5 to 101.5%) | 3.5 to 528 gpm | (0.8 to 636 m3/hr) |

| Low Flow (95% min) | 2.2 gpm | (0.5 m3/hr) |

| Max Continuous Flow1 | 528 gpm | (636 m3/hr) |

| Max Intermittent Flow2 | 880 gpm | (200 m3/hr) |

| Pressure Loss at Max Continuous | 1.45 psi | (0.1 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (60 °C) |

Notes

- 1 Max Continuous defined by AWWA as flow rate which can be maintained 24 hrs/day x 7 days/week

- 2 Max Intermittent defined as flow rate which can be maintained 1 hr/day average

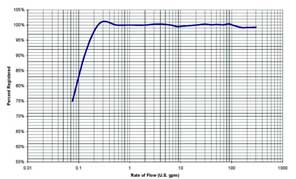

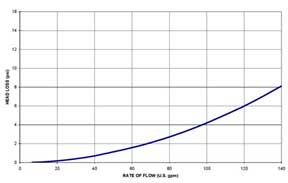

Flow Accuracy and Pressure Drop

| Flow Accuracy | Pressure Drop |

|  |

Registers

The innov8 electronic register is the water industry’s new standard for register performance. The innov8 offers maximum resolution, a multitude of standard features, on-board datalogging and a variety of cellular, AMI, AMR and SCADA output options. The innov8 is designed for all environments and incorporates the largest battery available for utility applications. The innov8 can be deployed on any Metron water meter.

Warranty

Please contact your Metron representative for formal warranty certificates.

Legal

Due to updated regulations and product improvements, Metron-Farnier reserves the right to change the product specifications without notice.

Enduro Fire Service Meter

Applications

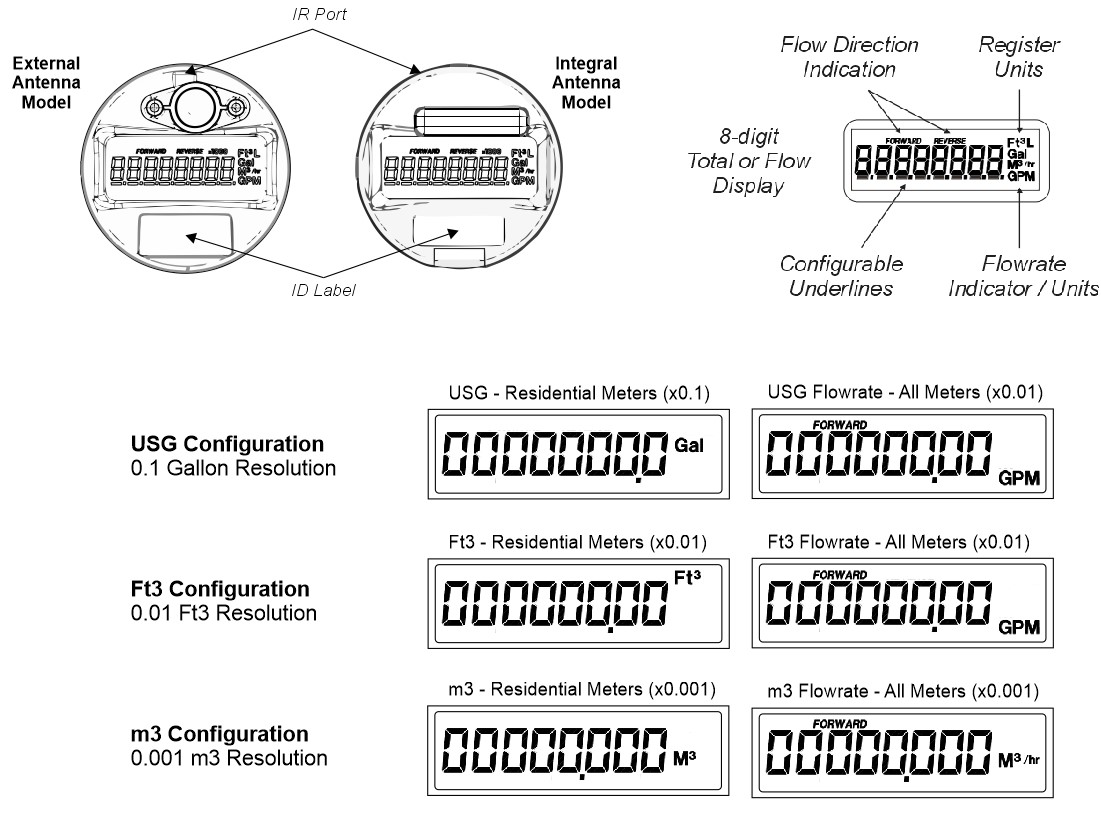

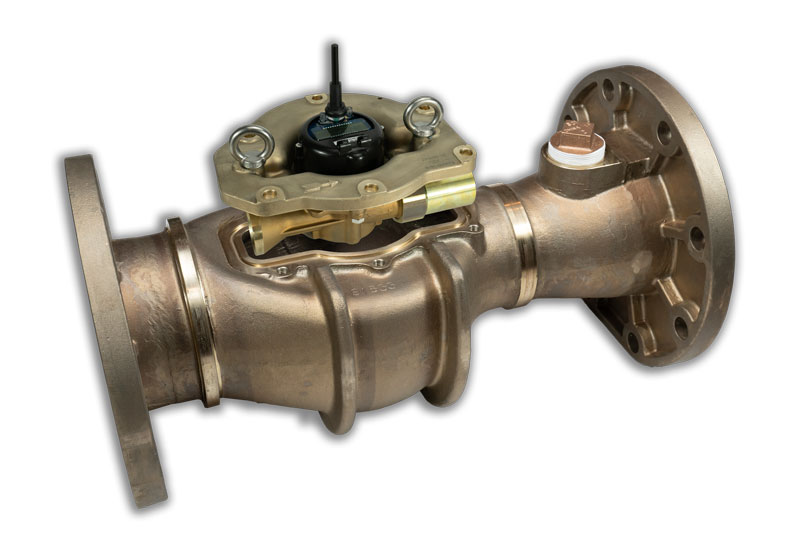

The Enduro water meters are single element, wide range industrial meters. The Enduro Model-D meters utilize a top-loading chamber to insert a small diameter Spectrum meter within the flow stream. This unique system allows for unparalleled accuracy and durability at both high and low flows within a compact meter body. The Enduro meters are an ideal solution for most industrial metering applications.

Fitting the Enduro with an innov8-VN register conveniently provides remote cellular-based readings via Metron’s Waterscope System. This allows the utility to track reads and consumption during the meter’s field time. An optional GPS unit also allows the utility to track the location of the meter on Google™ Maps.

Operations

Water enters the meter passing over an in-line water conditioner that directs the water through a small diameter Spectrum meter that proportionally measures the total water flow. This incoming water rotates a suspended impeller in the measuring chamber. A low friction pivot bearing supports the impeller at low flow rates while an upper thrust bearing provides the support at high flow rates. The impeller has an attached magnet at its top for the register interface.

To maintain accuracy, the meter must be installed horizontally (±10°) in the direction of water flow. Enduro meters come with an integral test port on the outlet. Although regular maintenance is not required, the Enduro meters have a top-loading measurement chamber for simple access without removing the meter from service.

All Enduro meters utilize innov8 registers. These sealed electronic registers provide a high resolution interface to the meter and have multiple output options. All registers are attached with a robust tamper-resistant housing.

Design Features

- High accuracy

- Wide range – 1000:1 turndown

- Superior low flow registration

- Minimal pressure loss

- Long-term durability

- Low and high flow models to accommodate variety of industrial applications

- No regular maintenance

- Small, compact design for simple installations

- Excellent performance in adverse conditions

- Unaffected by sand or small debris in line

- No straight pipe requirements upstream or downstream of meter

- Strainers available for FM Fire Service

- 5-year flange-to-flange warranty

Materials

All Enduro meters are designed and manufactured to meet

or exceed AWWA C712 standards design specifications. All Enduro meters meet or exceed AWWA C701 standards

Class II turbine meter performance.

All Models are maintained with NSF-61G lead-free certifications.

Standards

AWWA C712 – Single-Jet Meters

NSF-61G – Drinking Water System Components Health Effects

Mechanical Specifications

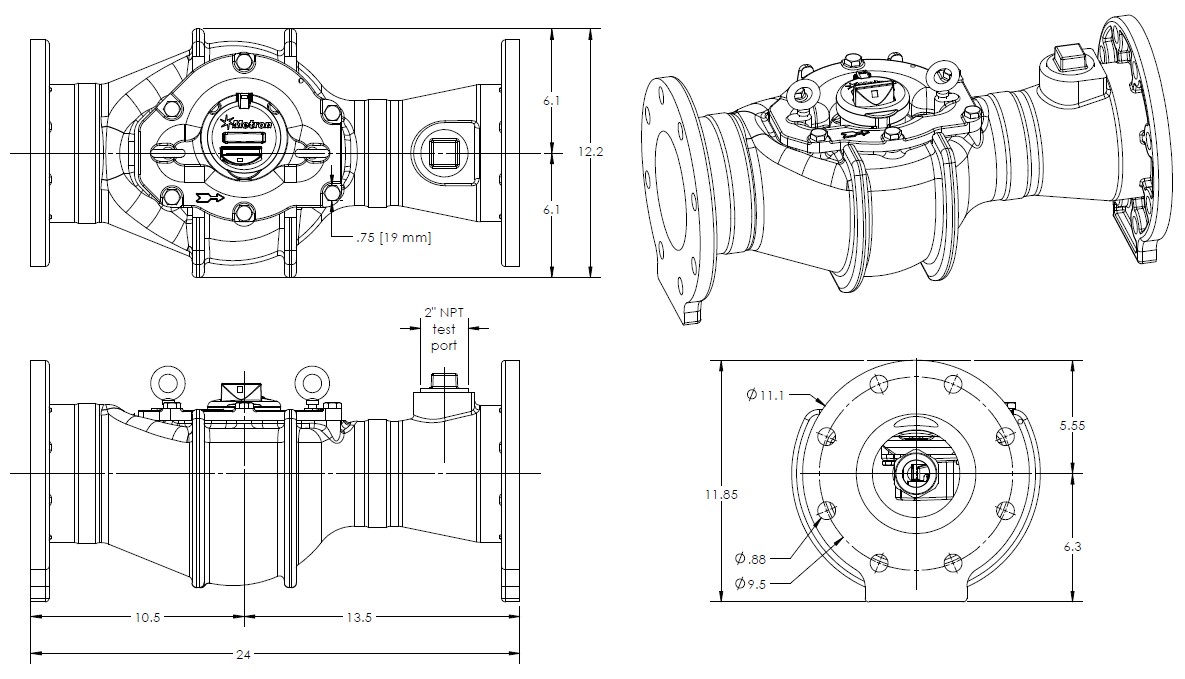

| Enduro 2800 | 6-inch (150mm) | 8-inch (200 mm) |

| Flanges | Round 8-bolt | Round 8-bolt |

| Lay Length | 24” (610 mm) | 24” (610 mm) |

| Dimensions | See drawing | See drawing |

| Weight | 109 lb (49.5 kg) | 138 lb (67.6 kg) |

| Test Port | Integral 2” NPT threads | Integral 2” NPT threads |

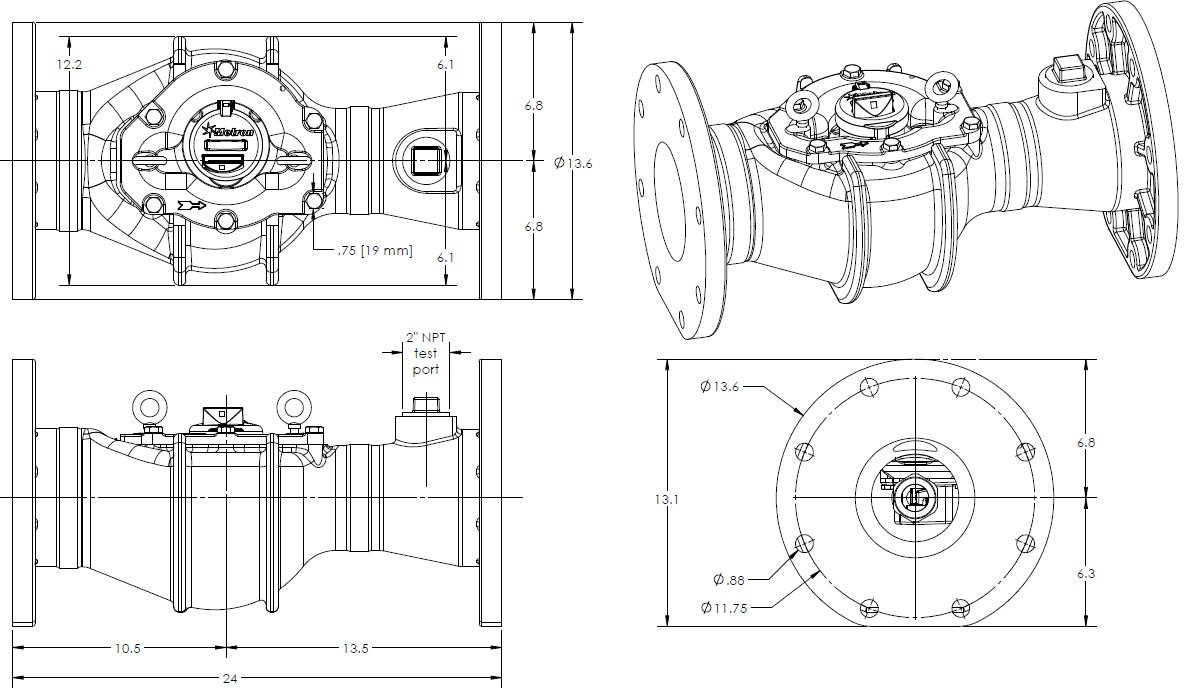

| Enduro 3600 | 6-inch (150mm) | 8-inch (200 mm) |

| Flanges | Round 8-bolt | Round 8-bolt |

| Lay Length | 24” (610 mm) | 24” (610 mm) |

| Dimensions | See drawing | See drawing |

| Weight | 109 lb (49.5 kg) | 138 lb (67.6 kg) |

| Test Port | Integral 2” NPT threads | Integral 2” NPT threads |

| Strainers | Fireflow-rated strainers available Contact Metron for additional information |

Materials

| Body & Top-plate: | ASTM C917 – Lead Free Brass |

| Impeller: | Polypropylene |

| Impeller Bearings: | Tungsten Carbide |

| Impeller Shaft: | AISI 303, Nivaflex tip |

| Register Housing: | Thermoplastic |

TAMPER FEATURES

| Register | Tamper-resistant screw |

Markings

| Engraved on Meter Body: | Model |

| Serial Number Date of Manufacture NSF-61G Direction of Flow |

DIMENSIONS

| Enduro 2800D / 3600D – 6-inch Model | |

| |

| Enduro 2800D / 3600D – 8-inch Model | |

|

Flow and Pressure Specifications

| Operating Range (98.5 to 101.5%) | 6 to 2800 gpm | (1.38 to 636 m3/hr) |

| Low Flow (95% min) | 4.4 gpm | (1 m3/hr) |

| Max Continuous Flow2 | 2400 gpm | (545 m3/hr) |

| Max Intermittent Flow3 | 2800 gpm | (636 m3/hr) |

| Pressure Loss at Max Continuous | 6.40 psi | (0.44 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Enduro 3600D– 6” and 8” Model

| Operating Range (98.5 to 101.5%) | 14 to 3600 gpm | (3.2 to 818 m3/hr) |

| Low Flow (95% min) | 8 gpm | (1.82 m3/hr) |

| Max Continuous Flow2 | 2800 gpm | (636 m3/hr) |

| Max Intermittent Flow3 | 3600 gpm | (818 m3/hr) |

| Pressure Loss at Max Continuous | 11 psi | (0.76 bar) |

| Max Operating Pressure | 230 psi | (15.9 bar) |

Max Operating Temperature | 120 °F | (48.9 °C) |

Notes

- 1 Starting flow rate for reference only

- 2 Max Continuous defined by AWWA as flow rate which can be maintained 24 hrs/day x 7 days/week

- 3 Max Intermittent defined as flow rate which can be maintained 1 hr/day average

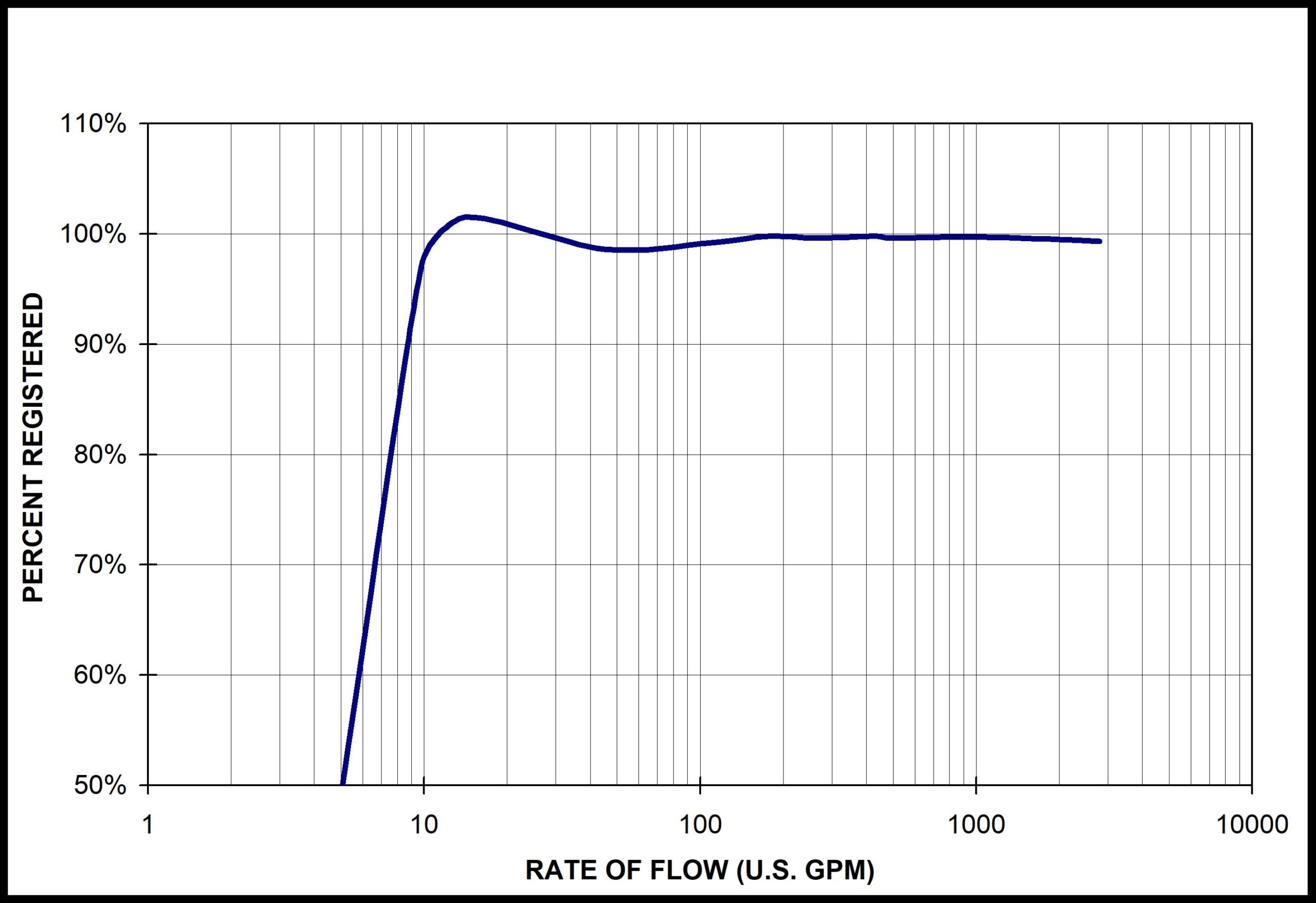

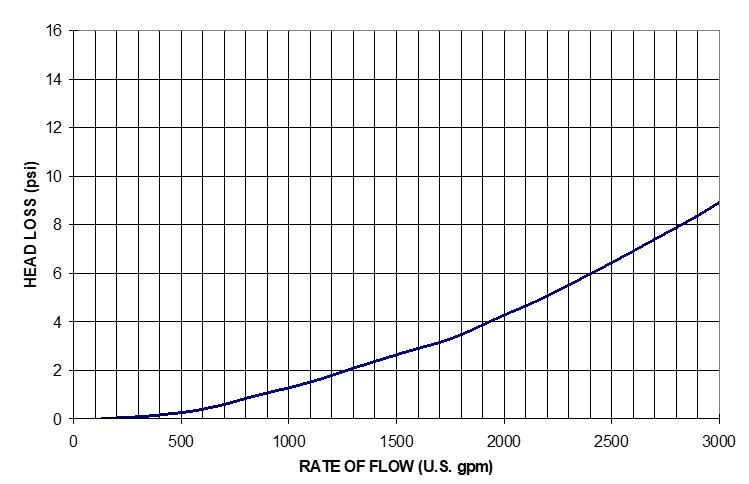

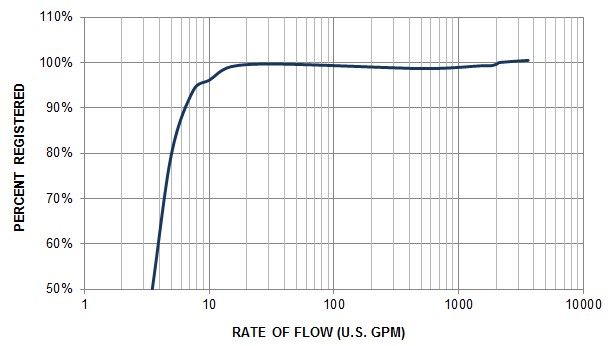

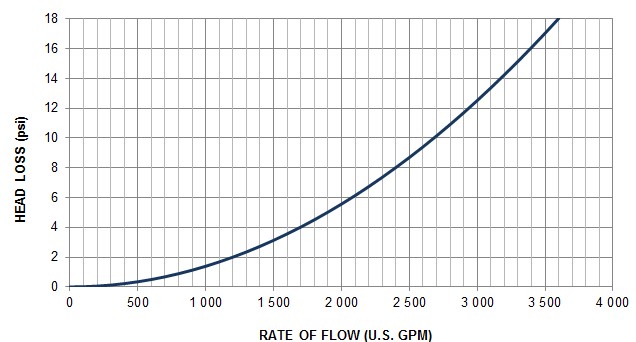

Flow Accuracy and Pressure Drop

| Flow Accuracy | Pressure Drop |

Enduro 2800D  |  |

Enduro 3600D |  |

Registers

The innov8 electronic register is the water industry’s new standard for register performance. The innov8 offers maximum resolution, a multitude of standard features, on-board datalogging and a variety of cellular, AMI, AMR and SCADA output options. The innov8 is designed for all environments and incorporates the largest battery available for utility applications. The innov8 can be deployed on any Metron water meter.

Warranty

Please contact your Metron representative for formal warranty certificates.

Legal

Due to updated regulations and product improvements, Metron-Farnier reserves the right to change the product specifications without notice.